500-MS: Ion trap from Varian as HPLC detector

We share our experiences with ion trap 500-MS from Varian:

- May 2016: 500-MS still running after 10 years!

- April 2010: Software update

- January 2010: Further applications of mass spectrometers 500-MS and 1200L:

- Fumonisin production by F. verticillioides and F. proliferatum: Mycol Res (2009) 113:1137-1145.

Mycotoxin production and adaptation of Fusarium to fungicides: Phytopathology (2010) 100:444-453.

Fumonisins in maize: Journal of Plant Protection Research (2009) 49:399-404.

Auxin production by truffle fungi: Plant Physiology (2009) 150:2018-1029. - September 2009: DESASTER: Oil in the system! How it happened - how much did it cost!

- Our first papers about metabolic profiling on 500-MS:

- Meatabolic diversity in sesame (440 kb): BMC Genomics (2008) 9:250

- Discovery of salicylic acid and SA-glucoside in xylem (330 kb): J Plant Res (2009) 122:571

- Our first paper about quantification on 500-MS:

- Detoxification of mycotoxin zearalenone (330 kb): Appl Env Microbiol (2007) 73:637

- July 2007: Conversion of Varian file format to netCDF

- June 2007 (pdf, 1.1Mb): Petr's presentation about metabolic profiling on 500-MS at ASMS meeting

- August 2006: Fast "unidirectional triple resonance scanning"

- May 2006: Installation

- - Sensitivity and signal/noise issues"

- - About settings

May 2016: Our 500-MS is ten years old

...and it still running! Obviously not state of the art but a realiable work-horse for daily routine. After we had to retire our HPLC-MS with triple quadrupole detector last year, we hope to install a new system in the fall.

April 2010: Software update

Perfect for 500-MS. For 1200L the last suitable version of MS Workstation is 6.9.1.

We updated MS Workstation which is the software controlling our mass spectrometers on both ion trap 500-MS and triple quadrupole 1200L. The updated MS Workstation on QQQ from 6.5 to 6.9.2 caused strange behavior. We replaced it by V6.9.1, which is the so far last version compatible with triple quadrupole 1200L, updated RAM of the PC to 4 GB and everything worked fine. The update to 6.9 (=6.9.1) from 6.5 was worth it:

- Copy & paste works in Sample List. We were longing for this feature!

- The following parameters can now be set separately for each time segment: needle voltage, shield voltage, drying gas temperature, dwell time... (Collision energy, of course, could be set separately for each segment in previous versions already.)

- Better access to control elements from the main windows.

There is a special updates of MS Workstation suitable for triple quadrupol 1200L (not just its follow-up model 320-MS). We are looking forward to install it. 1200L is a robust, reliable machine which has been the work horse in our lab since April 2004. Another 1200L is in heavy use in the next building (Faculty of Applied Geology, laboratory of Dr. Tobias Licha).

September 2009: How did vacuum oil get into 500-MS mass spectrometer

Suddenly and without an obvious reason, one of the rough pumps (photo below left) broke, releasing 300 ml of vacuum oil into the system.

Contamination of a mass spectrometer with vacuum oil is a worst kind of disaster because it is essentially impossible to clean the system such that the noise caused by traces of oil vanishes. Rough pumps from Varian are designed to prevent oil spill under all circumstances. The manufacturer ensures in the manual that the pump is equipped with a special antisuckback device to avoid backflow towards the evacuated vessel when the pump is switched off. This device has a shutter which automatically closes the suction duct. The device also posesses features preventing contamination of the inlet duct by fluids even when the pump is idle. In spite of these design efforts, one of our rough pumps HS652 happened to release 300 ml oil into the housing of 500-MS.

Challenge for Varian's technical service and our budget

The service staff of Varian is excellent but this was a real challenge. Service manuals do not deal with problems which are not expected to happen. A first technician replaced the pump and tubings and removed oil from the vacuum manifold inside the 500-MS housing but the re-assembled machine signaled a high foreline pressure. A second technician started replacing different parts related to the vacuum system of the machine, one by one. He replaced the vacuum gauge at the roughting pump manifold as this was contaminated with oil and could not be cleaned. The problem persisted. Apart from the foreline pressure, shield voltage became unstable. (Remarkably, the instability was only observed at one polarity setting and it sometimes disappeared temporarily when the machine was left over night.) A faulty power board was diagnosed and replaced. Connectors, cables and the needle of the electrospray were replaced, too. The foreline pressure was eventually fixed by replacing the vacuum manifold (roughing manifold), which was the part contaminated with oil at the very beginning.

The costs incl. VAT:

- Vacuum hose (photo above on the right): 690 €

- Vacuum gauge: 1058 €

- Power board: 8032 €

- Working time and travel costs of the technicians: 3957 €

- -------------------------

- Total costs of the repair: 13,737 €

Why were labor hours of the technician so expensive?

The service technician charges 210 € per hour (plus VAT). The costs were high because he worked for 12 hours, mostly by trial-and-error. He is the best expert on LC-MS I know, but the service manuals did not provide instructions on how to deal with the problem. With hindsight it appears to me that the contaminated manifold should have been replaced in the first place, but it is easy to be smarter afterwords; besides, the spare part was not available at the beginning, it took a while to get it from the U.S.

Why had we to pay for the failure of a pump to meet its specifications?

We paid for the parts directly contaminated and/or damages by oil, as well as for the replacement of the second pump which suffered while working against the dead first pump. (The costs of this pump are not included in the list above.) Varian replaced the broken pump free of charge and has not charged us for the vacuum manifold because it was not on a price list. (The manifold is a simple stainless steel container with a couple of inlets.)

I admit that we were not happy to pay for damages caused by a failure which the specification excludes, as well as for a long trial-end-error search for the cause of the problems. I do believe that Varian would have handled the issue differently in the past. I suppose that the recent acquisition of the company by Agilent for $1.5 billion generated a considerable strain, which limited their ability to act as fairly (or as generously, depending on your point of view) as in a normal situation. But I am sure that it is a temporary phenomenon. I do not blame Varian for the bill. What matters is that the machine is running again. We are lucky to have maintained a very good relationship with the company which services systems of critical importance for our work since we purchased our first MS in 2004.

July 2007: File conversion to netCDF

A drawback as compared to the software controling triple quadrupole 1200LC from Varian, which we got before the ion trap, is that 500-MS software does not support data export to the popular open exchange format ANDI/netCDF. NetCDF is necessary for data processing with most open source software packages. We use our 1200LC for this purpose: the software reads raw data from ion trap and exports them into ANDI/netCDF! If you don't have 1200LC, you need a convertor. ACD/MS Manager, for instance, reads 500-MS files and claims (we have not tried) to export open source netCDF files (single MS and LC(GC)-MS), see ACD/Labs.

August 2006: Fast full-scan on 500-MS

500-MS is well suited for comparative metabolite profiling because it offers high scanning rates (which means preserved chromatographic peaks) without jeopardizing mass resolution. The technology behind, distinguishing 500-MS from competitors' systems, is based on "unidirectional triple resonance scanning" (Int. J. Mass Spect 1999, 190: 129-143). The principle is to make use of an inhomogeneous electric field, which keeps ions out of the center of the trap, and let ions absorb energy from several kinds of the field at the same time, speeding up ion ejection and thus the whole scan.

Fig. 5 in document SI-0246_10_28_05_good_jb.pdf on Varian's website shows a striking example: isotope peaks of a singly-charged ion with a mass close to the upper limit of the trap (1800 Da), differing by just 1 Da, are fully resolved at the baseline at a scanning rate of 5000 Da/s.

The full scan is performed in three "mass segments" to reduce the mass discrimination inherent to ion traps: till 400 Da, 400 - 1000 Da and from 1000 Da to the upper limit 1800 Da. This information is important when one tries to maximize the sensitivity in fulls-scan mode. We have generated a number of full-scan chromatograms for the analysis of secondary metabolite profiles in the following systems: xylem sap of Brassica napus, extracts of seeds, shoots and roots of sesame (Sesamum indicum), cultures of numerous fungi and root exudates of Brassica napus, roses and - in collaboration with Dr. Claassen's group - of wheat, sugar beet and other plants.

May 2006: Installation

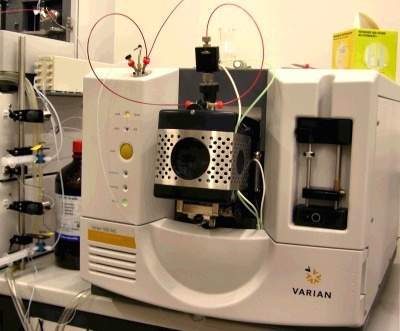

500-MS with ESI source installed (middle) and an integrated syringe pump (right).

In May 2006 we acquired a new HPLC-MS system from Varian, furnished with their brand new ion trap 500-MS. Our trap was the second 500-MS installed world-wide. Because of numerous inquiries concerning the system, we decided to share our experiences, performance data, solutions to problems and technical tips on this website.

We are continuously extending this website. Other users are welcome to contribute comments, performance data or protocols either directly to this site or as links to their own websites which we will be glad to present here.

Why ion trap?

We have been using HPLC coupled to triple quadrupole 1200LC from Varian for a year successfully, why do we need an ion trap? It was not because of its capability to do MSn for n > 2, the reason was our need for comparative non-targeted analysis of complex mixtures which requires fast full-scan capacity with a reasonable sensitivity. Quadrupoles have very low duty cycle values in full scan, because they discard most of the ions at any time except for ions with the m/z-value selected in that moment. This means that less than 0.2% of ions which enter the quadrupole will hit detector in a scan for m/z from 50 to 500.

Gain/loss of features as compared to 1200LC

The fundamental differences between 1200LC and 500-MC stem from the difference between triple quadrupole (QQQ) and ion trap technologies. However, QQQs and ion traps possess many similar or corresponding features. Because both systems were manufactured by the same company and operate side by side in our laboratory, we felt that it would be useful to report about features which we appreciate in one system and miss in the other one, as long as they are pertinent to both technologies. Today we start with two differences which we noticed most quickly: diverter valve and data export.

New feature: Integrated divertor valve

With 1200LC we installed an external diverter valve (red circle in the upper photo) according to a recommendation by Dr. Landgraff (Varian) to direct the eluate from column to waste rather than to the ion source, except during time windows in which the target analytes are expected to elute. Pure mobile phase, delivered by an extra HPLC pump, replaces the eluate during the "divert to waste" periods in order to keep the conditions within the ion source constant.

500-MS has an integrated six-port valve (lower photo) which can be used as a diverter valve. The drawback is that you cannot make use of the detector at idle times when a sequence is running, for example during column equilibration, when you use the built-in valve as a divertor. It is possible to install an external divertor valve in the same way as we did with 1200LC, but we decided to do without because we seldom need to use the detector while a sequence is running.

Lost feature: Export as netCDF

Although both triple quadrupole 1200LC and ion trap 500-MS are controlled by the same software (MS Workstation), the export of raw data to netCDF format disappeared in 500-MS together with other features (see figure below). Our workaround: import raw data from the ion trap system into MS Workstation controlling 1200LC, which allows you to export them as netCDF. If you don't have 1200LC and want to use ion trap data for purposes not anticipated by the designers of the software, you will need to buy a converter.

System control of triple quadrupol 1200LC (left) and ion trap 500-MS (right)

MS workstation software is complex, but efficient and user-friendly. The fact that there are two menus "File" is not confusing after one gets used to the difference. Notice the "Export" option in the unfolded menu. Unfortunately there is no "File" menu in the 500-MS window of MS workstation (photo right), and therefore no option for data export to netCDF.

Sensitivity, specifications and issues concerning signal/noise ratio

The guaranteed specifications for 500-MS with ESI are:

- Positive: 250 fg reserpine absolute, S/N better than 100.

- Negative: 5 pg nitrophenole absolute, S/N better than 50.

The performance determined during the installation (see conditions) was about 20-times better than the specifications; however, closer inspection of the data revealed that the software has an issue with the estimation of signal-to-noise ratio (S/N). The sensitivity appears satisfactory, but S/N estimates calculated by MS Workstation are flawed. We will explain this in detail in the following.

When evaluating performance or comparing different machines, S/N should be always estimated on unsmoothed data, because smoothing replaces measured signal intensities by values calculated from several neighboring data points (e.g., as a moving average in the simplest smoothing method), reducing the visible noise and artificially improving S/N values. The mode of the S/N calculation is important, too. Savitzky-Golay (a kind of weighted moving average) is usually the algorithm of choice for MS data. We performed different smoothings on the same peak in MS Workstation, had the software calculated S/N and obtained the following:

Unusual effect of Savitzky-Golay smoothing on noise

| Smoothing points | Noise | Signal | S/N | Chromatogram |

| unsmoothed | 1 | 7187 | 7187 | smooth0.gif |

| 3 points | 1 | 7187 | 7187 | smooth3.gif |

| 5 points | 2 | 5538 | 2769 | smooth5.gif |

| 7 points | 14 | 4723 | 337 | smooth7.gif |

| 9 points | 21 | 3998 | 190 | smooth9.gif |

| 11 points | 21 | 3438 | 164 | smooth11.gif |

It is normal that signal decreases with smoothing, but S/N should improve (until the smoothing scale gets too wide), otherwise there would be no point to perform smoothing! This is not the case with our data, because S/N continuously decreased with smoothing from 0 to 11 points. The reason was that noise was increasing rather than decreasing, effectively defeating the purpose of the procedure. The second problem was the replacement of noise value by 1 for raw data (and also for data smoothed over 3 points). There is obviously a software issue and Varian is dealing with it. It does not trouble us much, because having accurate S/N estimates is not crucial for our work as long as we can record good full-scan data.

About settings

As with every mass spectrometer, a number of parameters can be set with 500-MS to control the ionization interface and the ion trap itself. A couple of notes on topics which we felt were different from other mass specs might help new users traverse their learning curves faster.

Within a method, you define settings separately for each time window, which are designated "segments". It is important to realize what happens when you divert the eluate to waste and switch data acquisition off, as in the first and third segment in the method shown below:

During these idle times, the settings defined in the method are replaced by the defaults. This is important to keep in mind, for example, if the drying gas temperature is set to 300°C as a default and to 400°C in your method. If you don't want to change the temperature forth and back, you'd better set the defaults to the same temperature as used in your method. Unfortunately you have only one default setting: if you use different temperatures in your method (or several methods with different temperatures in one sequence) and have several "divert to waste" segments, you need to use an intermediate value as a default. We would carefully suggest that if one day Varian programmers find themself not having more important things to do, they might consider to allow the user to control some settings by the method even in Data Collection Off segments.

You stop data acquisition and disable settings specified in the method by unchecking the Data Collection box:

Changing drying gas temperature during acquisition

In this context we should mention that with 500-MS you can change drying gas temperature between segments, which is useful when you measure several substances in one run and want to squeeze out the maximum sensitivity for each. Equally interesting is the option to ramp the drying gas temperature continuously parallel with a gradient, because you can decrease the temperature along the elution gradient as the content of water in the mobile phase decreases:

We will extend this section occasionally. Generally, we found the management of settings on 500-MS very comfortable and more flexible as compared to 1200LC, which is understandable because 1200LC is a couple of years older.

Georg-August-University Goettingen

Grisebachstrasse 6

37077 Goettingen

Germany

FAX: +49 551 3912919